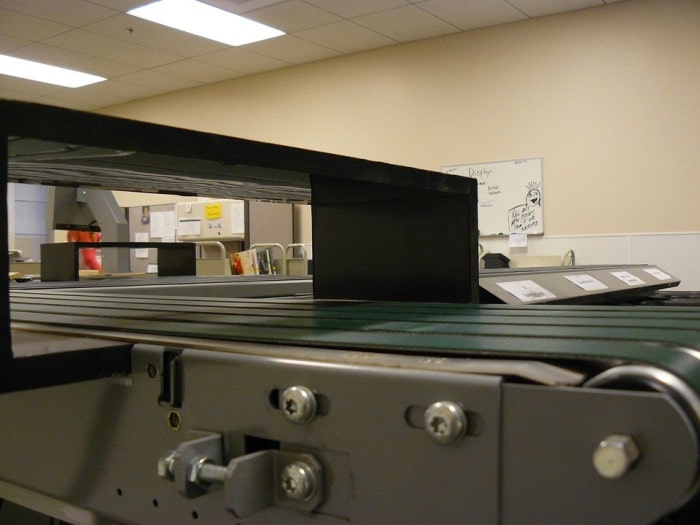

If you’re heading up a fast-paced distribution business, then chances are, conveyor belt maintenance is par for the course on your to-do list. Conveyor belts are complicated pieces of machinery that require care, attention, and above all a sharp eye for maintenance in order to operate efficiently and effectively on a daily basis.

Let’s take a look at how in five easy steps, you can stay on top of your conveyor belt and keep it running smoothly day in, day out by following this guide.

- Ensure employees understand the benefits of maintenance.

- Report problems before they become bigger issues.

- Keep machinery clean, tidy and in top shape.

- Stay on top of regular servicing and repair.

- Call in the conveyor belt experts if needed.

Step 1: Why Focus on Maintenance?

Ensure workers are aware of the value of maintenance. First and foremost, let’s establish the reason why keeping a conveyor belt maintained should be of the utmost importance in any distribution and processing business. One word, downtime. It’s a silent killer in the world of business and when machinery grinds to a halt, so too does production.

Establishing the importance of routine servicing firmly in the minds of your employees and workers is the first step in ensuring a regular, scheduled and effective maintenance program.

Find out more about the health and safety benefits of keeping machinery regularly maintained here.

Step 2: Keep an Eye Out for Issues

Before getting started in the morning, take the time to have a once over on your conveyer belt and make sure that nothing looks amiss, loose or untoward. If you spot a missing belt, sprocket, or wire hanging freely, fixing the problem before firing up the machine will prevent any further damage.

Poorly set up machinery is one of the leading causes of accidents in the workplace, so be sure to look out for problems at every opportunity. Get in touch with the experts at Fluent Conveyors for more information, parts and servicing, and a wide range of high-quality accessories for all your conveyor belt needs.

Step 3: Clean the Conveyor Belt

One fundamental element of maintenance is ensuring machinery is clean, free from dirt & debris and functioning as when it was brand new. Regularly cleaning and greasing moving parts will allow your conveyor belt to run without friction, minimising the impact of constant wear and tear. Closely following a regular cleaning schedule also allows machine operators to get a good look around a conveyor belt meaning any problems will be more likely to be spotted.

Step 4: Changing Fluids and Oils

Changing fluids on time extends the healthy life of a machine. In much the same way as a car operates, conveyor belts incorporate a system of closed gearboxes and regularly changing their oil will ensure a long and trouble-free lifespan. Over time and through continuous use, constantly moving components made of metal will degrade but fresh oil is the best way to combat metal fatigue.

Follow the handbook of your machine to the letter and replace oil on time with the recommended specification and grade.

Find out more about the importance of machinery lubrication and regular oil changes here.

Step 5: Seek Expert Advice

Of course, when running a business ensuring machinery is kept up and running plays a vital role, and it’s often tempting to just ‘give it a go’ when something breaks. This can be a fatal mistake however, and it’s often better to call in the experts.

When all is said and done, there will always be problems that can’t be fixed but attempting repairs without the correct knowledge can cause further damage to machinery. Be smart and get in touch with a company who knows exactly what needs to be done before setting to and causing a bigger problem.

In conclusion, there are multiple ways to maintain your conveyor belt in order to ensure it remains in top shape and able to carry out an array of demanding tasks. Be prepared to keep an eye out for when things are looking like a problem, and put a plan into decisive action in order to avoid issues getting out of hand. And finally, don’t be afraid to call in the help of an expert when it’s required.